Schottel announced September 29 that it has been selected to equip the new dredge Frederick Paup with a propulsion system consisting of three rudder propellers.

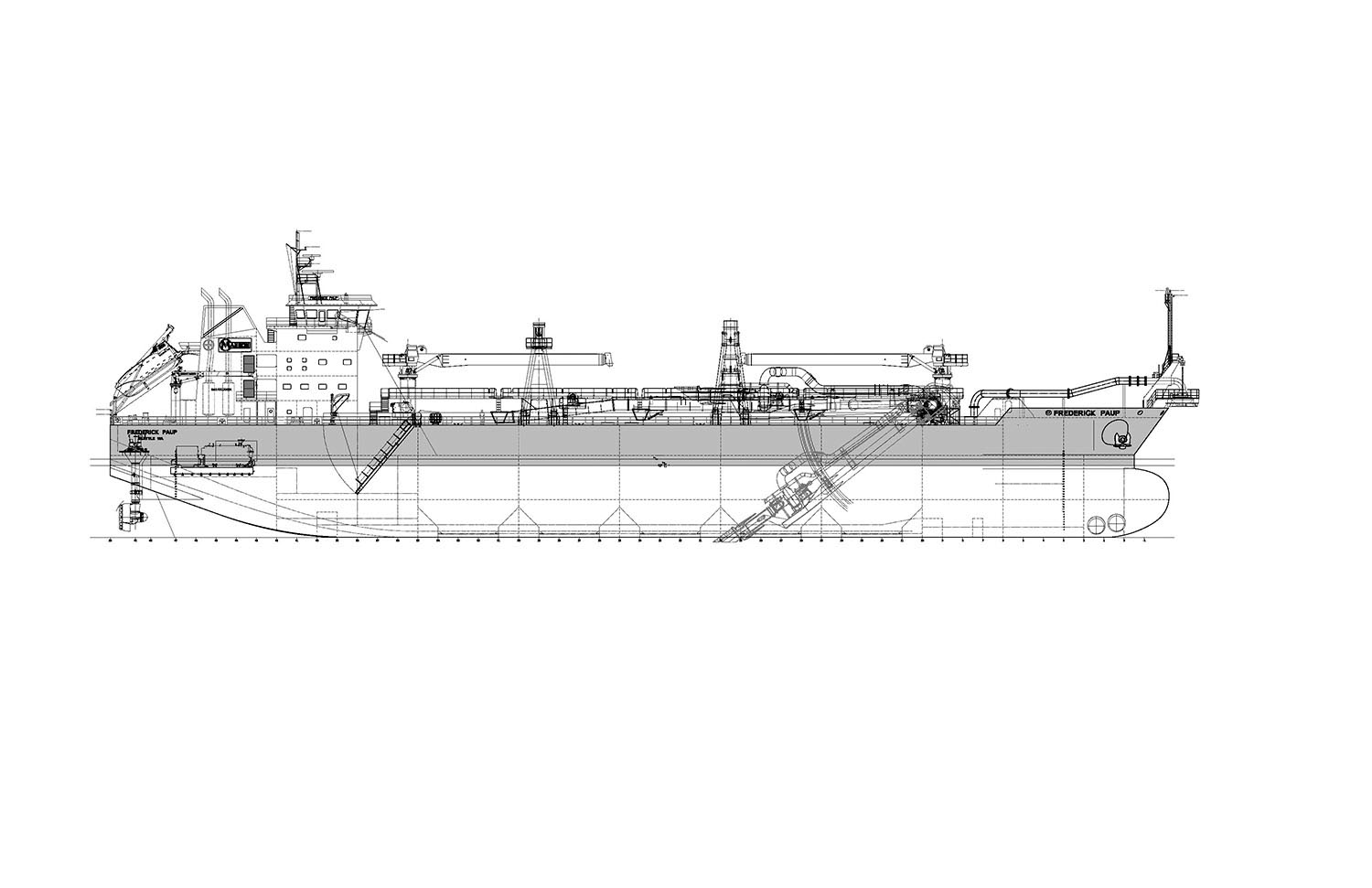

The Frederick Paup, now under construction at the Keppel AmFELS Shipyard in Brownsville, Texas, will be the largest U.S.-flagged, self-propelled trailing suction hopper dredge, with a hopper capacity of 15,000 cubic yards. The 420- by 81- by 28.5-foot vessel will be owned and operated by Manson Construction Company. (See WJ, September 28, 2020.)

“The Frederick Paup will set a new benchmark in the US hopper dredge market,” said Jordan Brown, project manager at Manson Construction. “The innovations include many aspects of improved ship design as well as specific demands regarding automation, machinery and equipment. Schottel was able to meet these requirements as the thrusters will optimally support our vision of top performance in terms of mounting, thrust and maneuverability.”

Hockema Group Inc., which designed the Frederick Paup, created a hull design concept that integrates the propulsion system. The aft appendages are optimally tailored to the rudder propellers in order to supply the thrusters with the lowest possible turbulence flow.

The three Schottel RudderPropellers are powered by diesel-electric drives and feature propeller diameters of 110 inches and a power intake of 2,240 kW each. A particularly long propeller arm length allows for an arrangement at the stern in portside, center and starboard position with convenient access for future maintenance.

The 360-degree-steerable rudder propellers will enable the Frederick Paup to always benefit from maximum maneuverability, outstanding course stability during free sailing and powerful thrust in the chosen direction. Besides the nozzles featuring enhanced corrosion protection with ProAnode, the RudderPropellers will be equipped with the DNV-GL type-approved Schottel LeaCon sealing system. Considered a non-oil-to-water interface, the system complies with the VGP regulations of the U.S. Environmental Protection Agency.

The Frederick Paup, named after Manson’s chairman, is being built to ABS requirements and is scheduled to enter operation in 2023. It will support the U.S. Army Corps of Engineers in maintaining marine transportation highways primarily along the Gulf and Atlantic coasts, as well as throughout the country.

Caption for photo: The Frederick Paup is under construction at Keppel AmFELS Shipyard for Manson Construction Company.