OSHA Increases Heat-Related Inspections At Maritime Facilities

By Greg Dillard and Austin Echols

Baker Botts LLP

As coastal temperatures continue to rise, many workers in the maritime industry are increasingly exposed to high-heat and high-humidity conditions, exacerbating their risks of developing heat-related illnesses.

To combat these risks, the Occupational Safety and Health Administration (OSHA) has begun developing workplace heat-safety regulations and concurrently implementing enforcement initiatives to mitigate heat-related hazards. Although it will likely be years before OSHA finalizes its heat regulations, the agency has put certain “high risk” industries—including many segments of the maritime industry—on notice that it is doubling unannounced inspections and increasing enforcement activity related to heat hazards.

(Note: facilities regulated by the U.S. Coast Guard’s health and safety standards, such as domestic vessels and offshore platforms, do not fall within the scope of OSHA’s NEP. However, if Coast Guard inspectors identify heat hazards at such facilities, they may coordinate with OSHA to address the hazards.)

Therefore, maritime employers should analyze working conditions at their facilities for potential high-heat exposures and implement written heat illness and injury prevention plans that, at a minimum, address worker training, water availability, rest periods and acclimatization.

OSHA Heat Standards

Despite being called on to regulate heat-related hazards for decades, OSHA has only recently initiated the years-long rulemaking process. The agency issued an advance notice of proposed rulemaking in 2021 and is continuing to seek public input on issues related to the standards’ scope and requirements. Because the regulations are years away, and will likely be further delayed by future federal court challenges, OSHA established an enforcement initiative aimed at preventing and protecting employees from serious heat-related illnesses.

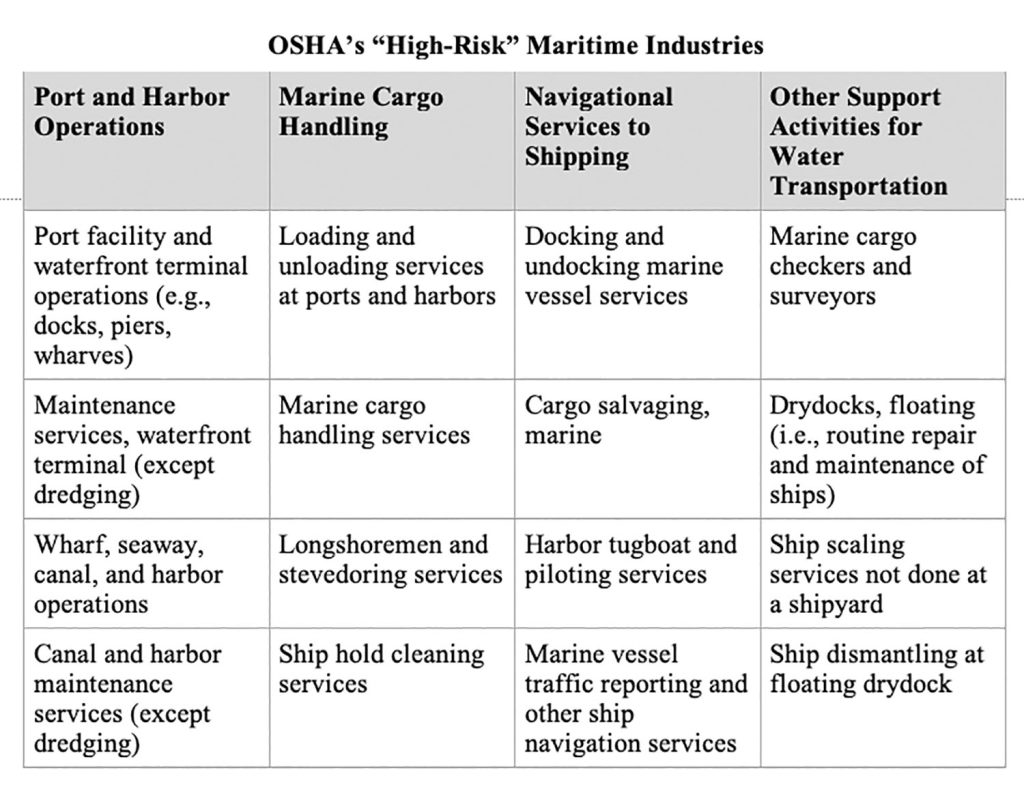

Earlier this year, OSHA doubled down on its enforcement efforts when it launched a National Emphasis Program (NEP) that gives the agency increased discretion to hold employers liable for heat-related risks in certain “high-risk” industries.

Heat Hazards NEP

Under the NEP, OSHA has doubled the number of unscheduled inspections at facilities in the maritime and other “high-risk” industries. OSHA considers high-heat hazards to exist whenever temperatures exceed 80 degrees Fahrenheit or the National Weather Service issues a heat warning or advisory for the local area. OSHA also explained that it will evaluate an employer’s heat-hazard prevention program whenever it is conducting an inspection for other reasons, such as those related to employee injuries or complaints.

The NEP also provides guidance to employers on how OSHA inspectors should conduct their unscheduled inspections. For example, inspectors are expected to evaluate whether the employer has an effective heat illness and injury program, including considerations such as:

• whether the program is written;

• whether the program includes heat-acclimatization periods for new and returning workers;

• how the employer monitors ambient temperatures and levels of work exertion;

• whether unlimited cool water and shaded rest breaks are easily accessible and available to employees;

• whether administrative controls like earlier start times and job rotations are used to limit heat exposures; and

• whether a “buddy” system of worker observation is used on hot days.

OSHA will also review OSHA 300 Logs and 301 Incident Reports for entries indicating heat-related illnesses and interview and observe workers for conditions that may indicate heat-related hazards, such as:

• working in direct sunlight or areas with hot air, like near gas engines or steam lines;

• wearing bulky clothing or using heavy equipment as part of their jobs or as personal protection equipment; and

• estimating workload exertions and durations of continuous or repetitive strenuous activities.

Prepare for OSHA

As maritime employers deal with 2022’s hottest months, there are several steps they should take to protect workers from heat-related concerns and to avoid scrutiny under OSHA’s NEP. Primarily, employers should analyze working conditions at their facilities for potential high-heat exposures and develop and implement robust written heat illness and injury prevention plans. In developing such plans, employers should also review their OSHA 300 logs from the past few years to quantify what injuries or illnesses, if any, are or could have been heat-related and implement plans to address those situations moving forward.

Maritime employers should be cognizant, particularly on hot days (those over 80 degrees), that OSHA may inspect their facilities for heat-related hazards. While OSHA’s past enforcement history of heat hazards has been checkered, OSHA has definitely strengthened its ability to enforce citations for unmitigated heat-related hazards. Therefore, employers needing compliance assistance with heat-related risks, inspections or citations should immediately contact legal counsel that is experienced in these fields.

About the authors: Austin Echols is an associate in the Houston office of Baker Botts LLP. His practice focuses on a range of environmental and health and safety issues, including within the maritime industry. Prior to practicing law, Echols served in the U.S. Coast Guard as a shipboard engineer, waterfront facility inspector and pollution investigator. He continues to serve in the Coast Guard Reserve, providing legal assistance to military service members, veterans, and their families.

Greg Dillard co-leads Baker Botts LLP’s incident response practice, focusing on safety and compliance for companies engaged in operating onshore and offshore oil, gas and chemical facilities across the upstream, midstream and downstream energy sectors. On any given day, he is an on-site responder, investigator, problem solver, innovator, counselor and crisis manager.