Drafting barges can be difficult work. The barges move, the numbers are often faded or rusted, and leaning over the edge to get an accurate reading can be dangerous. Bargetender is automating a tedious and necessary process into something safe and accurate.

The idea began when Trey Busch, a sales engineer specializing in industrial automation, was asked by a friend to check on the conveyor motor at his loading dock in Illinois. While there, Trey got to see barges being loaded and noticed deckhands going back and forth across them, attempting to read the draft numbers. His friend asked if he knew of any system that could read and record drafts for them, but he did not.

On the way home, Trey called his brother Taylor, a sales engineer based in Lake St. Louis, Missouri, and electrical engineer Dave Comisky, and the idea for Bargetender was born.

“Our whole lives, Trey and I have always tried to think of something that we could invent or create,” said Taylor Busch, co-founder of Bargetender. “We’d had hundreds of ideas over the years, but for some reason this one just felt right.”

The three decided to create a device that could calculate drafts based on the barge hull depth and distance to the water surface and then relay those measurements back to a user interface. Like most first prototypes, it wasn’t pretty.

“It was a long PVC pipe with a ninety-degree angle and a sonar transducer at the end,” Taylor Busch said. “Our first app was very basic, but it got the job done.”

The team of three made numerous trips back to the loading dock with their invention. They were able to read drafts like they’d wanted, but learned of other complications. Weather and barge movement were factors that made it difficult for their prototype to be efficient.

“How we conceptualized it, it really didn’t transfer to the real world,” Taylor Busch said. “But we kept asking questions at the dock and tried to really learn the loading process. In the meantime, we were trying to make it smaller and lighter.”

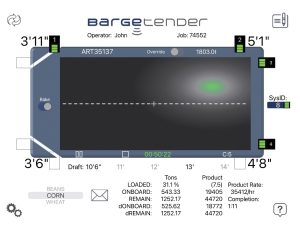

The Bargetender Automated Drafting System is composed of four 12.5-inch, 1-pound rechargeable radar sensors, which are placed in eight possible locations around the barge. Each sensor measures the distance from the barge surface to the water, taking multiple readings per second to account for waves. The Bargetender system displays the average draft measurements from each sensor on an iPad in real-time with an accuracy of a quarter inch or better.

“We want to provide accurate drafts, and the best way to do that is to sample at a high rate,” Taylor Busch said.

The Bargetender system does more than capture draft measurements. Users can input the current barge ID, and the system integrates barge registry data to provide the tonnage on board and the flow rate. Users can also record other inputs, such as draft targets, the commodity being loaded, tonnage goals, and more. The operator presses the play button when the barge is ready to be loaded, and the sensors relay the information back to the main iPad until the operator presses stop.

While the sensors relay all data back to an iPad, managers can keep track of progress even when away from the main system. Users can log in from their mobile device and access the Live View feature to check on load times, draft measurements, load rate, tonnage on board, bushel count, and more.

All data is private and saved automatically. Users can view their load history as well as import the information to Excel. The data can also be emailed automatically after each barge is loaded.

The Bargetender Automated Drafting System is currently being used at more than 135 docks across the country and has been used to load more than 65,000 barges and more than 80 million tons of product. ADM in St. Louis was the company’s very first customer. According to Taylor Busch, it was ADM’s interest in their idea that kept them moving forward.

“Looking back, it’s hard to believe ADM was willing to take a chance on us,” Taylor Busch said. “Their feedback and collaboration helped us tremendously. We are very blessed to be able to work with them.”

After several months of beta testing, ADM purchased another system for its site in Havana, Ill. After more successful testing, more systems were bought for locations on the Ohio River, and the Bargetender business began to grow.

“We thought, this is crazy, this is real,” Taylor Busch said. “People like it, and it’s helping from a safety standpoint, too.”

From there, word of mouth brought in more business. The Bargetender sensors are now being used across dozens of ADM facilities, as well as at Cargill, Viterra/Bunge, Consolidated Grain and Barge (CGB), Associated Terminals, ExxonMobil, Holcim, CHS, and more. While grain companies make up the biggest portion of their customer base, businesses moving products like coal, limestone, cement, aggregates and pet coke use the Bargetender system as well.

“There are other industries in addition to grain that also need to draft barges, and there’s a lot more out there we can still help with,” Taylor Busch said. “We’ve been very busy, and we’ve been really grateful for that.”

As the company grows, Bargetender is continuing to expand its industry reach. Arcosa-Wintech has been a partner with Bargetender, and Bargetender has also partnered with Bergan Marine Systems to bring its drafting technology into the tank barge industry.

For more information, visit www.bargetender.com or email sales@bargetender.com.

————

Featured photo caption: The Bargetender sensors are attached magnetically to the deck of the barge and provide real-time draft measurements and tonnage calculations. (Photo courtesy of Bargetender)