Caterpillar Marine has introduced the Advanced Variable Drive (AVD), a fully-integrated hydro-mechanical propulsion system that can be customized for any engine application, large or small, including dredges, auxiliary vessels and river towboats.

Power is generally installed to satisfy one of a number of applications and operates at a less than optimal load factor much of the time. The AVD system uses smaller engines that collectively provide the maximum power required and which operate individually at high load factors when full power is not required.

One of the most important features of the AVD is scalable power, said Nathan Kelly, technical leader of the AVD development team at Cat Marine in Lafayette, Ind. With the system, the installed power can be matched exactly to what is needed. The performance and response come from the hydrostatic system, he said.

The AVD incorporates a planetary gear set that allows seamless clutch engagement of main engines, auxiliary engines, or both to provide a scalable power installation fitted to the customer’s requirements for maximum power, vessel speed, or bollard pull.

A river tow running downriver on a straightaway can use an auxiliary engine that provides sufficient power for that activity. When encountering a bend or obstacle that requires more power, the hydrostatic system can instantly engage the main engine to produce more power or can reduce speed or even reverse without clutching in or out. The operator simply moves the throttle to increase or decrease power and speed.

There is redundancy in the system that adds safety, said Kelly.

“There is additional safety in terms of maneuverability in the event of a failure. You wouldn’t have full power, but you’d be able to propel the vessel with 75 to 80 percent power,” he said.

“With AVD, you have hydrostatic propulsion, mechanical propulsion, and hydro-mechanical propulsion. If one of your main engines fails, you can still power the vessel with both shafts using the hydrostatic system. If there is a failure of the hydraulic systems, there is still conventional mechanical direct drive for both propellers,” he said.

The AVD system is applicable on cutter dredges, which have cyclical load applications in cutter, pump and winch operations.

“A cutter suction dredge is an ideal application for the system,” said Kelly. “For high-load, cyclical applications with either a standard or multi-speed gearbox, the AVD could be a drop-in to increase efficiency,” he said.

Harbor Tug Design

Caterpillar Marine has partnered with Sanmar Shipyards in Istanbul, Turkey, to integrate the AVD into one of the company’s new tugboats. The compact harbor tug design includes 70 metric tons of bollard pull and firefighting (Fi-Fi) Level 1 capability.

Kelly is working with Sanmar to install the AVD system. All equipment, including the thruster and gear works, was delivered to Istanbul by the first week of December, he said, in preparation for building the vessel in 2019.

The Sanmar AVD tug will be the first hydraulic hybrid vessel of its kind, providing the same benefits as a variable speed diesel-electric propulsion (DEP) system at a fraction of the size and cost, the company said. Considering the perceived benefits of DEP systems, this is a tremendous accomplishment in terms of vessel design, Kelly stated.

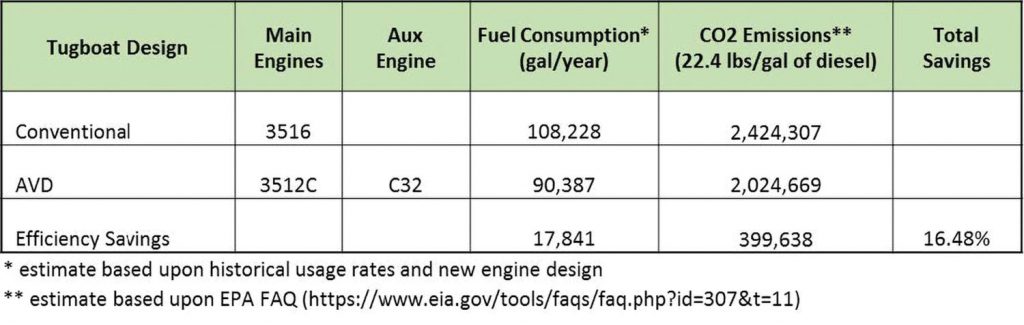

The design replaces two CAT 3516s with two Cat 3512Cs and one Cat C32. The hydraulic hybrid propulsion system selectively runs the engines (3512C or C32) at higher load factors, generating significantly higher fuel efficiency over conventional tugboats.

The 3512s will divide the annual work load of 3,000 hours per year. In contrast to running 3516s 100 percent of the time at a low load factor, the 3512Cs will only run 15 percent of the time (about 450 hours per year) at a much higher load factor. This optimizes the fuel efficiency and performance of the engines.

Most of the annual work load will be supported by the Cat C32 auxiliary engine, which will run 85 percent of the time (about 2,550 hours per year) also at a higher load factor, which optimizes fuel efficiency and performance.

The combined annual fuel use of the 3512Cs and C32 engines will be an estimated 90,387 gallons, opposed to an estimated 108,228 if 3516s were used. Based on historic usage rates and new engine design, the anticipated fuel efficiency and carbon dioxide emission savings are estimated at 400,000 pounds of carbon per year. This is based on an estimate of 22.4 pounds of carbon dioxide emissions per gallon of diesel fuel.

The ability to run with the main engines off reduces wear and tear and therefore service and maintenance costs over the life of the engines and their components. AVD motors and components are smaller and less expensive than battery-electric hybrid systems.

When fully integrated into vessel design, the propeller speed can operate independently of engine speed, and optimal engine efficiency can be achieved, even with a fixed propeller. For the Sanmar AVD tug, this savings is estimated at 15 to 20 percent.

The ability of the system to rely mostly on its auxiliary engine dramatically reduces owning and operating costs and extends engine and component life well beyond what is currently practiced.

The AVD reduces maintenance costs and has conventional service requirements. It can be scaled to meet the requirements of a wide range of vessel types, applications and power levels, and enables effective downsizing of engines without the loss of performance.

Electric motors can be used instead of hydraulics if required. AVD enables straightforward integration of diesel, natural gas or gas turbine engines or any combination of these as prime movers, accommodating various levels of engine load acceptance capability and engine speed regimes.

The AVD technology was first developed by Caterpillar as the Dual Path Variator for use in the mining industry and was introduced in 2012 on the Cat 966XE medium wheel loader. AVD is the marine propulsion designation for this technology.

To introduce the technology to the marine industry, Nathan Kelly delivered a technical presentation on the AVD at the 2018 Asia Pacific Maritime (APM) conference in Singapore in March. Engineering manager Igor Strashny presented on the AVD at the Electric and Hybrid Marine World Expo in Florida in January 2018, and Jim Mundth, territory sales manager for Caterpillar Marine, described the system during a panel discussion at the Western Dredging Association (WEDA) 2018 Dredging Summit and Expo in Norfolk, Va., in June.

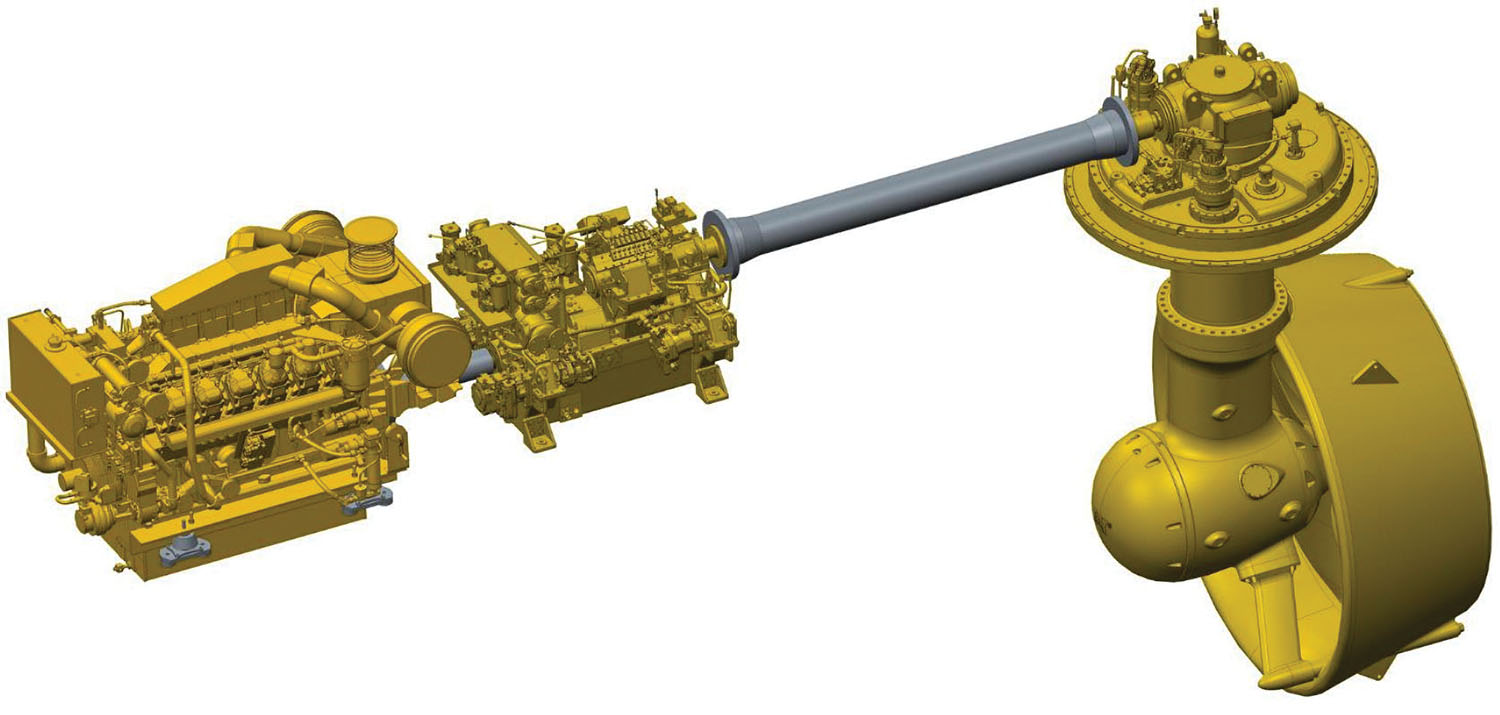

Caption for top photo: The Caterpillar AVD shown connecting an engine and a hydrostatic motor to a single propeller. This design allows the engine and other systems to operate independently of the propeller, improving performance and increasing fuel efficiency.