When Sunshine, La.-based Chem Carriers put the mv. Brooke Banta into service in 2011, Louisiana maritime industry veteran Warren Berthelot was there, having shepherded that project to completion as the company’s chief engineer. The Brooke was the first of three vessels Chem Carriers built with Z-drives. The other two are the mv. Frank Banta Jr. and the mv. Capt. Robert J. Banta, both retractables.

And now, roughly 12 years after the Brooke Banta first went to work for Chem Carriers, Berthelot has overseen its repowering, with a new set of Mitsubishi main engines from Laborde Products and a pair of Steerprop thrusters from Karl Senner installed at Verret Shipyard, where he now serves in a similar role.

Rodriguez Boat Builders in Bayou La Batre, Ala., built the hull of the Brooke Banta, with Chem Carriers completing the vessel at its Plaquemine Point Shipyard, which was sold to VLS Environmental Solutions about a year ago. Originally, the 70- by 28-foot towboat offered 1,200 hp. from a pair of Mitsubishi S6R main engines, which turned Z-drives from ZF.

Over the years, though, the Brooke Banta lost a number of kort nozzles due to electrolysis attacking the bolts that held on the nozzles.

“When you lost a nozzle, it just looked like someone took a wrench and took the bolts off,” Berthelot said. “Electrolysis just ate them completely up.”

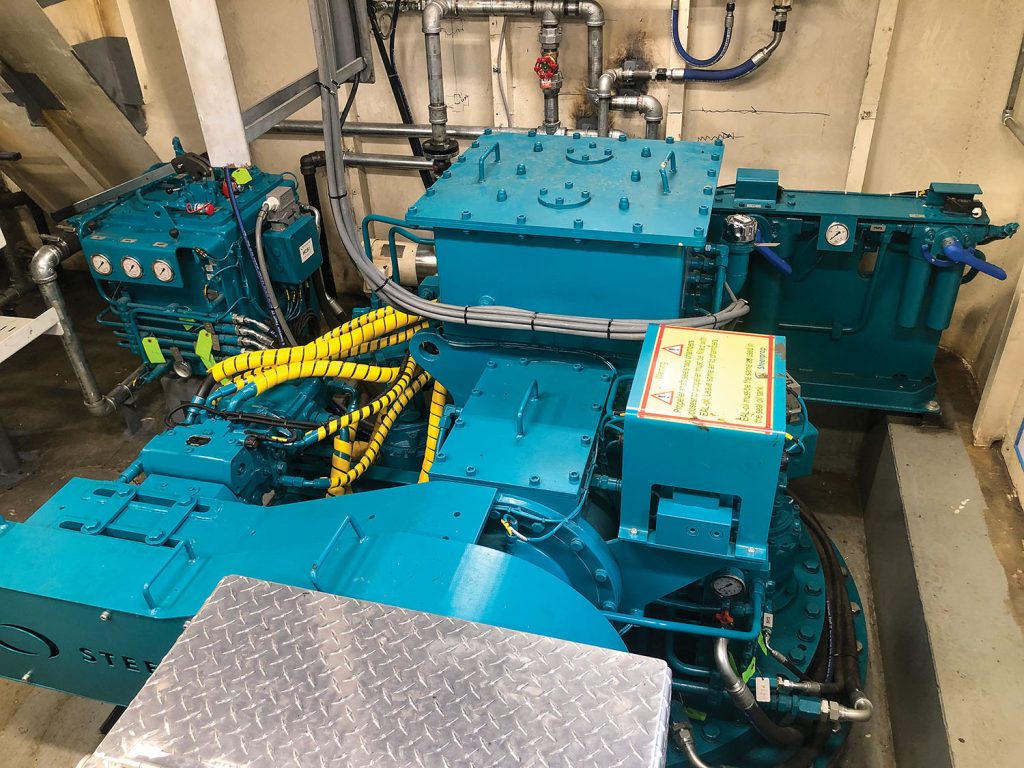

When Chem Carriers made the decision to switch from ZF thrusters to Steerprop, though, Berthelot and the Verret team had to solve a different problem: literally, how to fit a round peg in a square hole. While the ZF thrusters bolted up to a square hole in the hull, the Steerprop thrusters are round. To make the Steerprop units fit, Verret needed a pair of adapter tubs.

“I had a fabricating company called Deltak that actually made the tubs,” Berthelot said. “We had to cut the square boxes out, install these tubs, weld them, recess them a certain depth so the lower unit would be in the right position.”

Berthelot noted that, with a Steerprop thruster, the reduction takes place within the unit. Thus, it had to be machined in place, after the thruster was already welded in place.

“We hired a company called SKF to actually machine it in place,” he said. “They did a laser alignment while we were there.”

In addition, because the Steerprop thrusters require a longer drive shaft from the engine, the shipyard had to extend the engine foundation in order to move the engines forward a bit. Normally, Berthelot said, with a similar application there wouldn’t be a conventional engine foundation. However, when Chem Carriers was building the Brooke Banta, under his direction, they opted for one anyway.

“We did that in case the Z-drive didn’t work out so that we’d have a foundation in the engineroom that tied the aft bulkhead and forward engineroom bulkhead together,” he said, “We were able to continue with that foundation to the very stern of the boat.”

Berthelot thanked Robin Robert with Karl Senner, Kent Hoffmeister with Global Technologies, Deltak Corporation and Kevin St. Pierre with SKF for partnering with Verret to make the switch to Steerprop thrusters a success. In addition, he thanked Matthew Coombs with Christie & Grey for the anti-vibration mounts aboard the Brooke Banta.

Beyond the thruster changeout, Verret also exchanged the Brooke Banta’s original S6R main engines for a pair of Mitsubishi’s S6R2 Tier 3 mains. That upped the per-engine horsepower from 630 to 803 for a total of 1,606 hp.

“It really pushes and performs good,” he said. “The package is really smooth.”

Berthelot said the conversion started around April and took a little over two months.

Still Going Strong

Berthelot, 78, said his career in the maritime industry goes back to 1965, but he actually grew up on the Mississippi River, near Mile 197 in the town of St. Gabriel, La.

“We used to catch shrimp in the river,” he said. “It was a real delicacy.”

Berthelot eventually moved to the Baton Rouge area, where he remains today.

He worked for Chotin Marine until Kirby acquired the company in 1992, then worked for Kirby for a while. He later worked as an engineer and dealer for Reagan Equipment, then joined Chem Carriers. Berthelot came on with Verret Shipyard in 2019, when Verret was building the mv. Lee W for Enterprise Marine. The Lee W is a huge 138- by 38-foot retractable towboat.

At the end of that project, Berthelot thanked Verret Shipyard owner Ted Verret for the chance to do what he loves doing.

“‘I don’t have any hobbies, and I have very few friends, so this has always been my love, building boats,’” Berthelot recalled saying to Verret.

According to Berthelot, Verret replied, “I didn’t know you were going anywhere. I thought you’d stick around.”

“He was just chomping at the bit,” Verret said, adding that Berthelot remains fully engaged and active on projects at the yard. “He’s our project manager. He’s 78 years old and still puts a wrench in his hand.”

Berthelot said he wouldn’t have it any other way.

“When I wake up in the morning, it’s not like I’m going to a job,” he said. “I never considered any portion of my career work, because I always enjoyed it. I guess that’s why I’m still out here. I don’t want to turn into a slug, sitting in my recliner and eating and not getting any exercise and losing contact with the world.

“If you separate yourself from society, it doesn’t take long, when you get back out there, to get run over,” he added. “Things change so fast.”