Since acquiring Empco-Lite nearly four years ago, the Edgecombe family has taken a deliberate, operations-driven approach to expanding the company’s footprint on the inland river system and along the Gulf Intracoastal Waterway. Now operating as a women-owned, family-led business, Empco-Lite is building on its long-established manufacturing base while sharpening its focus on marine customers. The company is positioning itself as a dependable lighting partner for barge towing and dredging operators navigating America’s working waterways.

The acquisition was finalized in June 2022 after delays tied to the COVID-19 pandemic. In the months that followed, leadership prioritized gaining a detailed understanding of the company’s internal processes before pursuing market expansion. As Will Edgecombe explained, the early emphasis was on readiness rather than speed.

“When we closed, the priority wasn’t growth for the sake of growth,” he said. “It was learning the operation and making sure we could support customers the right way before pushing further into new markets.”

Empco-Lite serves multiple transportation sectors, including highway safety, aviation, rail and marine, supported by a vertically integrated manufacturing model. All plastic components are molded in-house while electronics are assembled locally through a nearby contract manufacturer. Final assembly and testing are completed at Empco-Lite’s facility, a structure that provides consistency across product lines.

From Liam Edgecombe’s perspective, that level of control is especially valuable in marine environments, where reliability and lead times are critical.

“Because we control the plastic molding and final assembly, we’re not waiting on finished goods from overseas,” Liam Edgecombe said. “We know what’s going into every unit, and that allows us to maintain consistency and accountability.”

Marine lighting has been part of Empco-Lite’s portfolio for decades, but, under the Edgecombe family’s ownership, it has become a more intentional area of focus. Todd Puffpaff, who has spent nearly 30 years with the company and now serves as sales director, has watched the marine line evolve alongside distributor relationships and operator feedback.

“Marine lighting originally grew out of distributor relationships,” Puffpaff said. “They were already serving traffic control and marine customers and asked if we could build a portable barge light. From there, the product line continued to evolve.”

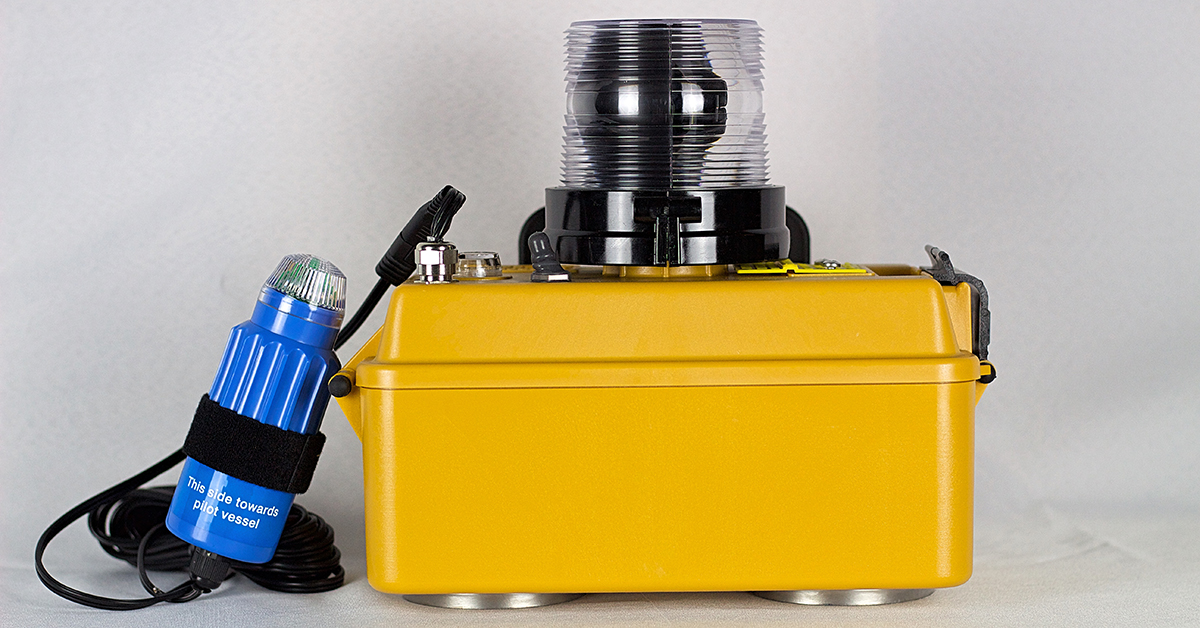

Today, Empco-Lite offers a range of portable marine lighting solutions designed for barges, dredges and fleeting areas. The lineup includes amber barge lights as well as red and green navigation lights that meet U.S. Coast Guard visibility requirements.

“Our navigation lights meet the 2-nautical-mile requirement for bow and stern applications,” Puffpaff said. “Dredging lights also require 2 nautical miles, but they use a different battery configuration.”

A defining feature of Empco-Lite’s marine products is their portability. Rather than relying on permanently wired systems, the lights are designed as self-contained battery-powered units that can be deployed and repositioned as operational needs change.

While the external plastic housings have remained largely unchanged for many years, internal technology has continued to advance. The company has intentionally preserved a proven design while investing in performance improvements within the unit.

“The housing design has been the same for 15 to 20 years because it works,” Puffpaff said. “Where we’ve focused is on the electronics—moving from xenon to LED, increasing output, updating processors and improving circuitry to meet Coast Guard requirements.”

From a maintenance standpoint, the lights are designed to minimize downtime. In most cases routine service consists primarily of battery replacement, and the rugged construction allows the units to withstand harsh working conditions.

“You really have to beat these things up to damage them,” Puffpaff said. “They’re built for real-world use.”

As Empco-Lite expands its reach within the inland and Gulf barge and towing markets, distributor growth is a central part of the strategy. The company already works with marine distributors but sees opportunity to broaden those relationships and introduce the brand to new operators.

“A big part of what we’re doing now is awareness,” Will Edgecombe said. “Letting customers know who we are, what we offer, and that we can support them reliably.”

Domestic manufacturing remains a core part of that message. Liam Edgecombe emphasized that being family owned and American made continues to resonate within the marine industry, particularly when paired with responsive service.

“Customers want to know who they’re dealing with,” he said. “Being family owned and manufacturing here helps build trust.”

Service and quality control remain cornerstones of Empco-Lite’s approach. Customers are able to reach knowledgeable staff directly, and every product is tested before shipment.

“Nothing leaves here without being tested,” Will Edgecomb said. “That’s a standard we don’t compromise on.”

While no new marine products are currently slated for release, the company is closely monitoring broader industry trends, including greater integration between physical equipment and fleet management systems. Leadership views this evolution as an opportunity to align future development with customer needs while maintaining the company’s focus on durable, dependable products.

With consistent production capacity, short lead times, and a growing emphasis on marine applications, Empco-Lite is positioning itself to play an expanded role on inland and Gulf waterways.

“As demand grows, we’re ready to grow with it,” Will Edgecomb said. “The foundation is solid, and that puts us in a good position moving forward.”

Featured image caption: An Empco-Lite barge light, which comes in a variety of colors.